How Does Heat Treating Work? How Does it Strengthen Steel?

If you put the time and effort into creating steel products—from knives to artwork to machine parts—you want to make sure they’re up to the task and built to last.

That’s what heat treating is all about. A critical final step in making anything with steel, heat treating is a process of heating and cooling metal. It fundamentally alters the molecular structure of steel to improve a variety of important properties.

Let’s take a closer look at how heat treating works and what it’s good for.

How Does Heat Treating Strengthen Steel?

The science of heat treating is complicated. But at a high level, here’s what’s happening.

When you heat steel to its critical temperature, also called the austenitizing point, the steel’s atoms begin to vibrate and move around. This temp range varies by the type of steel. It sets the stage for all sorts of modifications to the internal structure and properties of the steel.

When you cool the steel, all that atomic activity slows. The atoms lock into fixed positions and form stable bonds—strengthening the steel.

How much and how fast you heat your steel affects the final properties. The same goes for your cooling rates.

Precise control of these parameters helps achieve the characteristics you need, such as strength, hardness, toughness, ductility, elasticity, and wear resistance. Learn more about heat treating basics.

Why is Heat Treating Important?

Durability is a key consideration for many steel products.

For example, heat treating helps maximize the hardness and wear resistance in high-stress and abrasive environments.

In automotive applications, heat-treated steel parts demonstrate enhanced strength, toughness, and fatigue resistance.

For knifemakers, heat treating helps optimize edge retention—for knives that stay sharp cut after cut. A related process called tempering (more on that below) also improves durability by reducing the brittleness of the steel.

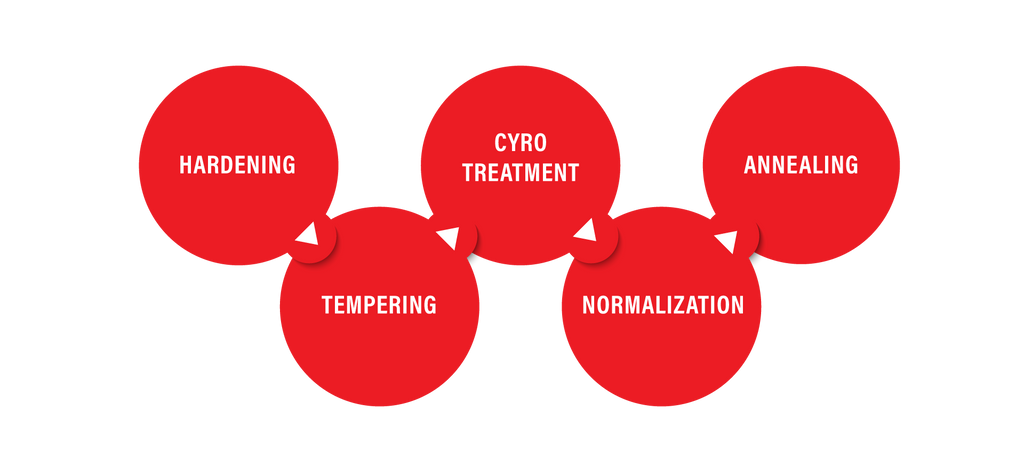

Types of Heat Treating

Controlling and tweaking your heating and cooling parameters leads to a full range of final properties and characteristics.

In general, heat treating processes fall into the following categories.

Hardening

Hardening involves three main steps: heating your steel past its critical hardening temperature, holding or “soaking” it there for a short period of time, then rapid cooling—also called quenching. That last part often involves submerging the part into oil or water.

The process leads to a more stable and crystalline molecular structure. This newly increased hardness also improves wear resistance, durability and all-around performance of a lot of products, including (but certainly not limited to):

- Industrial machinery – gears, bearings, shafts

- Aerospace parts

- Tools and dies

- Knives and other cutting tools

Case Hardening

What if you only need the surface of your steel product to be hard?

Case hardening is up to the job. You still heat the metal above the critical temperature. But the rapid cooling step is focused on the surface—hardening the outside while the core remains softer and more ductile.

This more complex process can happen in several different ways:

- Carburizing involves heating the steel in a carbon-rich atmosphere or a molten salt bath.

- Nitriding uses a nitrogen-rich atmosphere.

- Induction hardening heats the steel surface with a high-frequency induction coil.

Case hardening is great for parts such as gears, bearings, and shafts.

Annealing

The annealing process also involves heating steel to its critical temperature. But after that, it differs from hardening in a key way. Instead of quenching fast, you cool the metal slowly.

Unlike hardening, annealing softens the metal to make it easier to machine and less likely to crack. The process also involves subjecting the metal to high heat. But unlike hardening, you cool the metal slowly.

This slow cooling allows the steel to transform from the high-temperature, unstable austenite phase to a low-temperature, stable phase called ferrite. The results include:

- Increased ductility

- Reduced hardness

- Improved machinability

- Reduced stress

Annealing is common in the production of many low-carbon alloy steels, including wire, sheet metal, and tubing.

Tempering

The hardening process puts quite a bit of stress on steel. It can come out of heat treatment very brittle.

That’s why hardening is often paired with tempering. This process reduces internal stresses by reheating the material—this time to a temperature that’s below its critical temperature.

Think of it like a warm, relaxing bath for the steel, if you like.

Tempering does reduce the hardness you’ve achieved. But nobody wants a knife that chips or breaks easily. By easing internal stresses, tempering makes steel less prone to cracking or chipping. So the slight hardness tradeoff is often worth it for knives, automotive parts, manufacturing molds, and many other products.

Case hardening is a heat treatment process that produces a hard outer surface on a metal object while leaving the inner core softer and more ductile. This is in contrast to standard hardening, which hardens the entire object uniformly.

Normalization

Normalizing refines the grain structure of steel, removes impurities, and improves mechanical properties such as strength, toughness, and ductility.

As with hardening and annealing, normalizing involves heating steel to its critical temperature. But in this case, you let it cool at a moderate rate at room temperature—slower than hardening, faster than annealing.

By refining the grain structure, normalizing can help prepare steel for further processing. It’s a common way to optimize the performance and reliability of steel components for automotive, aerospace, machinery, construction, manufacturing, and other industries.

How to Do Steel Heat Treating Right

You could send out your products to a commercial heat treating shop. But they often have long lead times, and the costs can quickly add up.

Another option is to do it yourself! With a bit of knowledge and the right equipment, you can make sure your steel products have all the properties you need.

Speaking of the right equipment: Hot Shot offers a high-quality line of made-in-the-USA heat treating ovens. With precise control, easy operation, and Cool-Touch Technology for safe placement anywhere in your shop, they’re a smart choice for those who want to heat treat at home.

Ready to bring it in-house? Contact our experts for help getting started.